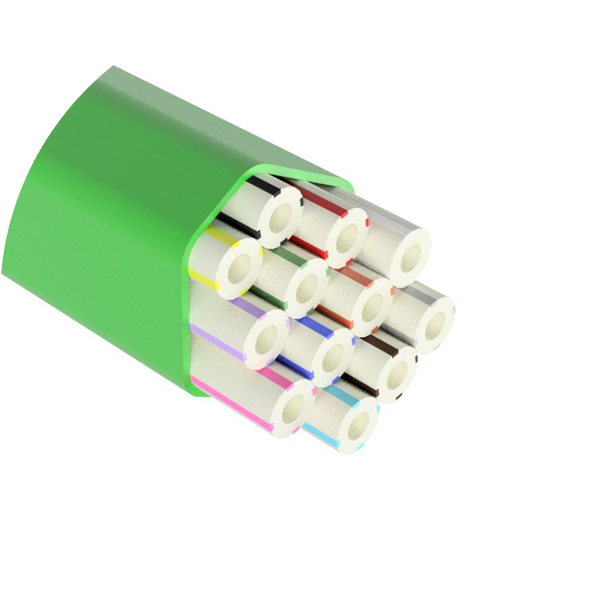

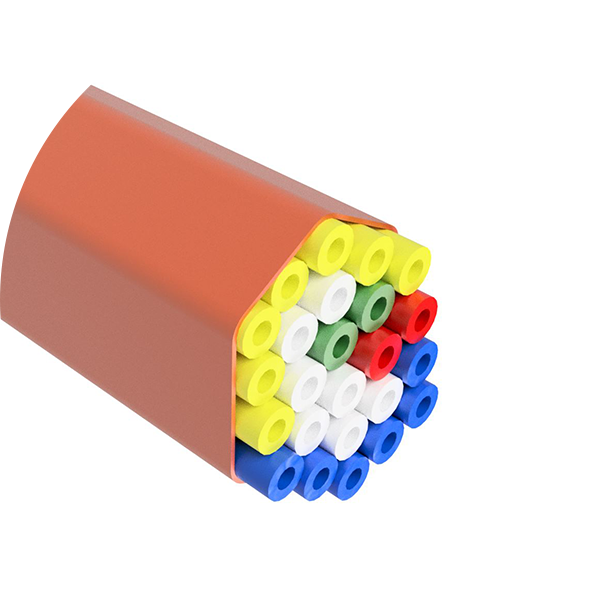

DB Assemblies – Metal Free

Single Sheath

These robust MiniGlide™ assemblies are designed to provide a strong and simple solution for direct burial into prepared ground. These are suitable for use in traditional trenches, narrow trenching and micro trenching installations.

They comprise of heavy-duty crush-resistant thick-walled HDPE microducts and a thin sheath of PE or PP which holds the bundle together. Fast and easy to install, these assemblies offer a cost-effective solution to your network build.

All Radius CTS microducts feature our low friction and low static permanent inner layer which delivers class-leading cable blowing performance. In addition, our microducts can be supplied with either smooth or ribbed inner walls according to your preference.

What is Low Friction coating?

A solid layer of lubricant is evenly distributed on the inner wall by coextrusion as part of the manufacturing process, providing a permanent low friction and low static surface which lasts for the life of the duct.

Low friction values allow quicker installation and optimal blowing distances. Radius CTS microduct offers superior blowing performance in this market.

Low Friction Matters

Fast cable installation into ducting is key for cost effective, low disruption network build. Cable blowing is the method of choice for longer routes whereby cables are propulsed into the ducting using compressed air.

The blowing distance achieved is directly related to a number of factors including : cable to duct area fill ratio (we recommend 50 to 60% ideally but no more than 70%); weight of cable; pressure used, route difficulty (bends and gradients) and last but not least the Coefficient of Friction (CoF) from the microduct inner lining.

The contribution of the microduct inner lining to achieving speed of installation and longer blowing distances should not be underestimated. A quality lining should have the right combination of low CoF and low static for optimum results and for that reason, not all linings are created equal.

Class Leading

Friction Properties

At Radius CTS, we have spent years of careful formulation and testing to achieve our class leading low friction and low static inner coatings. Our low friction compounds are home crafted, no ready-made mixes there!

And the results speak for themselves in the field where for the last 30 years we have helped our customers achieve proven consistent long install lengths thanks to our high-performance low friction coating.

Features & Benefits

- Simple and robust assembly

- Suitable for Direct Burial, Micro/Narrow Trenching

- Heavy duty thick-walled microducts

- Low friction for optimum blowing performance

- Metal Free

- Many configurations available from 1 to 24way

- Bespoke solutions are available

Why Low Friction Matters?

Sizes

| Type | Configuration |

| 4/2.1mm | 2, 4, 7, 12, 19, 24, 24+1way |

| 7/3.5mm | 2, 4, 7, 12, 12+1, 19, 24, 24+1way |

| 7/4mm | 2, 4, 7, 12, 12+1, 19, 24, 24+1way |

| 8/3.5mm | 2, 4, 7, 12, 12+1, 19, 24, 24+1way |

| 8/4mm | 2, 4, 7, 12, 12+1, 19, 24, 24+1way |

| 10/6mm | 2, 4, 7, 12, 12+1way |

| 12/8mm | 2, 3, 4, 5, 6, 7, 12way |

| 14/10mm | 2, 3, 4, 5, 6, 7way |

| Type | Configuration |

| 16/10mm | 2, 3, 4, 5, 6, 7way |

| 16/12mm | 2, 3, 4, 5, 6, 7way |

| 18/12mm | 2, 3, 4way |

| 18/14mm | 2, 3, 4way |

| 20/14mm | 2, 3, 4way |

| 20/15mm | 2, 3, 4way |

| 20/16mm | 2, 3, 4way |

Options

Microducts:

- Inner Wall: Smooth or Ribbed

- Colour: Solid / Translucent / Stripes

- Numbering

- Customer Specific Print

- UV Stabilisation

- Pre-Cabling

Assembly:

- Tracer Wire

- Ripcord

- UV Stabilisation

- Striped Sheath Option

Certification

- Made to ISO 60794-1-21 : 2015 & ISO 60794-5-10 : 2014

- Duct can be manufactured to BS EN 61386-24 : 2010

- Duct can be manufactured to SKZ HR 3.54 : 2019-07

Installation:

- Direct Bury (DB)

- Drop

- Narrow Trenching

- Open Trench

- Underground

Applications:

- Backbone

- Campus

- Drop

- FTTh

- Last Mile

- PIA