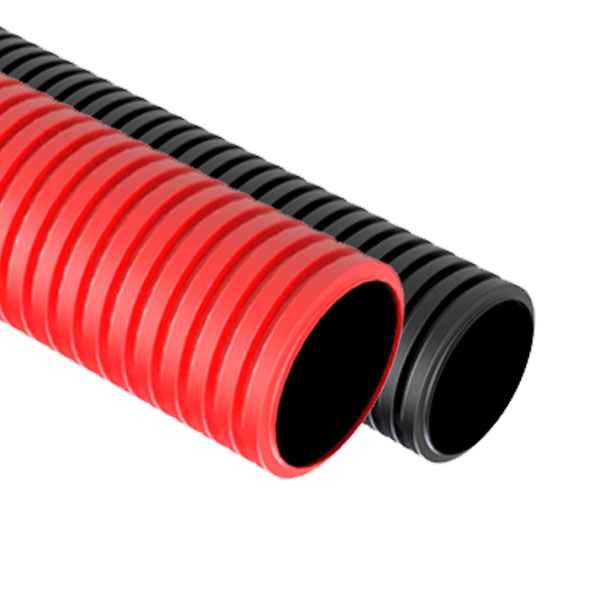

Twinwall HDPE Duct

Electric Cable Duct Class 2&3

Radius Power Twinwall ducting range complies with ENA TS 12-24 Class 2 and Class 3 specification and provides excellent cable protection and fast underground installation for underground Power networks.

Radius Twinwall is a light, yet robust solution for cable protection. Manufactured from high density polyethylene (HDPE) with a corrugated outside wall and smooth inner wall, Twinwall ducting is rigid, yet flexible and easily outperforms alternative products.

Twinwall HDPE duct has a high static and dynamic load bearing capacity combined with high impact resistance. The smooth inner bore combined with the lower frictional coefficient of HDPE, reduces the effort required to install long lengths of sub-duct and cable.

The inherent flexibility of Radius HDPE Twinwall duct allows high speed building and significantly reduces the number of bends required during construction, particularly for local loops. HDPE is also less brittle than PVC and is easily recycled.

When specified, we can supply a full O-ring sealing system to prevent the ingress of silt and water.

What is ENA TS 12-24

Class 1, 2, 3 ?

ENA is the Energy Networks Association which represents the cables and pipes Transmission and Distribution network operators for gas and electricity in the UK.

ENA TS 12-24 is the technical specification issued by the ENA for plastic ducts for buried electric cables and defines the essential performance requirements and limiting dimensions, colour and identification details for coiled and non-coiled, plain or corrugated wall, circular cross section, extruded plastic cable ducts.

Class 1, 2 & 3 ducts protect low, medium/high voltage cables operating at 11kV, 33kV and EHV up to 132kV.

Class 1+ 450N at 75°C

Class 1+ electric cable duct means that the ducting provides 450N compression strength at 75ºC and in addition, is manufactured from high grade PE100 material that satisfies the test requirements for pressure rating defined in Clause 16.6 of ENA TS 12-24. Manufactured in either black or red colour.

Class 1 450N at 75°C

Class 1 electric cable duct means that the ducting provides 450N compression strength at 75ºC. Manufactured in either black or red uPVC or HDPE.

Class 2 450N at 50°C

Class 2 electric cable duct means that the ducting provides 450N compression strength at 50ºC. Manufactured in either black or red uPVC or HDPE.

Class 3 450N at 23°C

Class 3 electric cable duct means that the ducting provides 450N compression strength at 23ºC. Manufactured in either black or red uPVC or HDPE.

Features & Benefits

- Complies with ENA TS 12-24 Class 2

- Lightweight with high ring stiffness

- Good impact resistance, even at low temperature

- Each length is supplied with a fitted coupler

- Flexible – fewer joints required

- Easily repaired

- Environmentally friendly

- Can be customised to meet user requirements

What's ENA TS 12-24?

Sizes

| Class 2 ENA TS |

||

| OD/IDmm | Lengths | |

| 110/95 | 6m | |

| 118/100 | 6m | |

| 145/125 | 6m, 3m | |

| 178/150 | 6m, 3m | |

| Class 3 ENA TS |

||

| OD/IDmm | Lengths | Coils |

| 63/50 | 6m | 50m |

| 110/95 | 6m | 50m |

| 118/100 | 6m | |

| 145/125 | 6m | |

| 160/125 | 6m | 50m, 25m |

| 178/150 | 6m | |

Other lengths available subject to MOQ.

Standard colours:

Options

- O-Ring Sealing

- Customer Specific Print

- Custom lengths subject to MOQ

Certifications

- ENA TS 12-24

- BSI Kitemark to BS EN 61386-24 : 2010

- BBA approved for 110mm, 118mm, 145mm 178mm OD

What's ENA TS 12-24?

Certifications

- ENA TS 12-24

- BSI Kitemark to BS EN 61386-24 : 2010

- BBA approved for 110mm, 118mm, 145mm 178mm OD